ELECTRO-SENSORS

I. INTRODUCTION

Electro-Sensors, Inc. began operations in 1968 in St. Louis Park, Minnesota. It was founded to serve material handling and process control applications in industrial plants.

Electro-Sensors, Inc. consistently produces the most reliable machine monitoring sensors and hazard monitoring systems, utilizing leading-edge technology to continuously improve our products and make them easier to use. Our goal is to manufacture the industry-preferred product for every market we serve. We do this through total quality commitment, by completely fulfilling our customers' expectations.

Electro-Sensors, Inc. contributes real value to the marketplace by providing complete, ready-to-install systems. These systems are delivered promptly and are supported by knowledgeable technical support, providing total customer service. We appreciate our many loyal customers who depend upon our products every day to help run their plants with greater efficiency, productivity, and control.

No matter how unique or complex your manufacturing environment, chances are that Electro-Sensors has encountered a similar challenge. A dedicated staff of applications engineers and years of experience combine with the industry's most advanced technology to deliver reliable solutions that can perform at or above industry standards.

Our product list:

- Shaft speed switches

- Shaft speed sensors

- Shaft speed pulse generators/ Shaft speed target

- Temperature sensors

- Bearing sensor & belt allignment

- Slide gate & angle position

- Tachometers, counters, displays

- Vibration & tilt

- Motor-drive-control

- Accessories

- Wireless hazard monitoring

- Hazard monitoring

- Signal conditioners & interface

II. PRODUCTION

- Shaft speed switches

A speed switch senses rotating shaft speed, comparing it to one or more settable over/under/zero speed alarm trip-points. A shaft speed sensor detects magnets embedded in a shaft-mounted pulser wrap/disc. As the shaft rotates, the passing magnets are detected across an air-gap as pulses with frequency proportional to shaft RPM. When the pulse frequency (shaft RPM) crosses to the alarm side of a trip-point threshold, a corresponding relay de-energizes, indicating the alarm.

- Shaft speed switches function/ Application?

- Zero Speed Switch - A switch used to determine if a rotating shaft comes to a complete stop.

- Overspeed Detection - Utilizing a Speed Switch to monitor a shaft for speeds that exceed the determined setpoint.

- Underspeed Detection - Utilizing a Speed Switch to monitor a shaft for speeds that fall below a desired setpoint.

- Reverse Speed Detection - The detection of a shaft which not only stops but begins to rotate backwards.

- Combination sugesstion:

Shaft Speed Switch + Shaft Speed Sensor + Shaft Speed Pulse Generator

Shaft Speed Switch with Integrated Shaft Speed Sensor + Shaft Speed Pulse Generator

- Shaft speed switches Product series:

- SCP1000 / SCP2000 (Best seller)

- SS110 (Best seller)

- M100T / M5000T

- DR1000

- LRB1000 / LRB2000

- FB420

- UDS1000

- M100 / M5000 PVC100 / 5000

Shaft Speed Sensors

https://www.electro-sensors.com/products/shaft-speed-sensors

- Shaft Speed Sensors features:

- Large Gap, Non-Contact Sensing

- Pulse (NPN, PNP) or 4-20 mA Output

- No User Calibration

- Single or Quadrature (bi-directional) outputs

- Explosion Proof (XP), Intrinsically Safe (IS) and Dust-Ignition-Proof (DIP) Options

- Rugged and Reliable

- Easy to Install and Set Up

- Shaft Speed Sensors Product series:

- ST420/ ST420-LT/ ST420-DI (Best seller)

- 906 XP / 907 XP hall effect (Best seller)

- 1101 Hall effect sensor

- 931 XP Hall effect sensor

- 1102 / 932 / 933 XP

- 1201 / 1202

- Series 18

- HE950

- 916A / 917A (replacement only)

Pulse Generator Features/ Shaft speed targets

Shaft Speed Targets are needed to generate a pulse for a Speed Sensor that is monitoring a shaft for RPM (Revolution Per Minute). Electro-Sensors Pulse Generators provide the shaft speed target needed for shaft speed detection with a sensor or switch

- Pulse Generator Features/ Shaft speed targets Features:

- Varying Magnet Counts (PPR)

- Face or Edge Read Pulser Discs

- Nylon, PVC, Stainless Steel, Aluminum

- End-of-shaft or clamp around mount

- Narrow and Standard Size Pulser Wraps

- High Speed Options

- Custom Designs

- NEMA C Frame Ring Kits

- Pulse Generator Features/ Shaft speed targets Product series:

- Split Collar Pulser Wraps

- Pulser Discs

- Magnet Wheels

- Digital Ring Kits

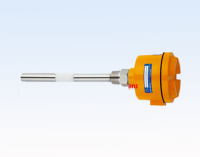

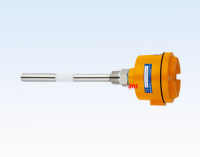

Temperature sensor2

Electro-Sensors TT420 and TT420-LT (Liquid-Tight) 4-20 mA temperature sensors can be used to monitor temperature on a wide range of industrial machinery including conveyors, bucket elevators, motors, gearboxes, pumps, turbines, fans, curing ovens, centrifuges, agitators and hammer mills.

- Temperature sensor Feature:

- 2-wire, loop-powered 4-20 mA analog output

- Attachment probe, sensor and 2-wire 4-20 mA signal conditioner in one

- No user calibration: works right out of the box

- Reverse-wiring protected

- Compatible with PLCs, meters, and data acquisition systems

- Patented Design (TT420-LT)

- Intrinsically Safe (IS) and Dust Ignition-proof models available

- RTD Sensors with 3-wire Platinum Pt100 RTD output

- Temperature sensor Product series:

- TT420/ TT420F/ TT420S/ TT420Z

- TT420-LT/ TT420Z-LT/ TT420S-LT

- TT420-WT/ TT420Z-WT

- RTD-LT Half-Inch / RTDS-LT/ RTDZ-LT

- Bearing Sensors & Belt Alignment

Bearing temperature measurement with the patented TT420Z-LT (Liquid-Tight) family of temperature sensors offers superior performance, ease of installation, and industry standard 4-20 mA outputs. All temperature sensors are factory calibrated and are available with various probe lengths, conduit adapters, and grease fittings.

The patented TT420S-LT (Liquid-Tight) temperature sensors are used to monitor leg and conveyor belt alignment with three versions of rub block doors. All temperature sensors are factory calibrated and come with straight or right angled conduit adapters.

- Bearing Sensors & Belt Alignment Product series:

- TT420/ TT420-LT

- RTD / RTD-LT

- RUB BLOCK DOOR ASSEMBLIES

- MODEL TA

- MODEL DB

- MODEL PC

- MODEL RS

- MODEL RSB

Slide Gate/ valve position & Angle Position sensors

- Slide Gate & Valve Position Sensors overview

All six Position Feedback Monitors in the SG1000 Series provide independent and accurate feedback of a slide gate's or a valve's position to an external device such as a PLC or optional PM500 Process Meter Display Unit. Models are housed in a rugged, explosion-proof cast aluminum enclosure that is dirt, dust, grease-proof, and water resistant.In the case of a power failure, all SG1000s are designed to retain accurate gate position.

- Two relay slide gate position sensor overview

The SG1000RA is a stand-alone system for those looking to accurately monitor gate end-point positioning or equipment. With a two-relay output, the SG1000RA can control equipment, lights, horns, or other various facility alarm systems. After a simple set-up, the SG1000RA triggers its relays once the slide gate reaches its fully-open or fully-closed positions. Just like the other SG1000 models, the SG1000RA is housed in an explosion-proof enclosure that is dirt, dust, grease-proof, and water resistant.

- Slide Gate/ valve position & Angle Position sensors Features:

- Absolute Encoder-Based Feedback

- 4-20 mA or Two-Relay Output

- Valve, Gate, or Shaft Position Feedback

- Non-volatile Memory

- UL and CE Approvals

- Easy 1-, 2-, or 3-Point Calibration

- Slide Gate/ valve position & Angle Position sensors product series

- SG1000/ SG1000A/SG1000B /SG1000C / SG1000D/ SG1000E/ SG1000F/ SG1000RA

- PM500

- Tachometers, Counters, and Display

- Tachometers, Counters, and Display Features

- Displays Include; Rate, Time In Process, Product, Sum, Difference, Ratio, Draw Process, Batch, or Total Counting

- Field Adjustable, Full Diagnostic Functions

- Built-In Relay Testing Capabilities

- Highly Programmable

- Single-Channel or Bi-Directional Counting

- Setpoint and Start Delay Functions

- Multiple Relay and Analog Output Options

- Keypad Lockout

- Tachometers, Counters, and Display product series:

- TR400 (Best seller)

- TR5000 (Best seller)

- AP1000

- PM500

- CT6000

- HH100

Vibration & Tilt

- Vibration & Tilt Features:

- Detect Presence or Absence of Bulk Material

- Protect Machinery Against Excessive Vibration

- Monitor Vibration on Deliberately Vibrating Machinery

- Heavy-Duty Vibration Monitoring

- Explosion Proof Housing Options

- Adjustable Vibration Alarm Trip Point

- Vibration & Tilt Product series:

- VT420

- VS1/ VS2

- MTS SERIES & SCU-200

- VUM800

Position Monitors & Motor Drive Controls

- Position Monitors & Motor Drive Controls Features:

- Four motor speed drive control models ranging from a simple speed dial/display to complex machine/process synchronizers

- Capable of many motor/machine control schemes, from open-loop master to closed-loop pulse-locked speed/event synchronized follower

- Compatible with all motor speed drives of any size/power rating with an analog input (AC, AC Vector, DC and Servo)

- Position Monitors & Motor Drive Controls

- SG1000

- MS196/ MS320/ MS332./ MS332

- ACCU Series

- Hazard Monitor: SENTRY 1 / SENTRY 16

- VS Series: VS1/ VS2